Automation Solutions

Alliance Rubber Company is also a proud provider of banding automation solutions. Our Automatic Rubber Banding Machines provide a more efficient way to apply rubber bands to your product. Whether you want to increase productivity or eliminate repetitive motion injuries within your operation – our machines perform excellently in demanding production environments.

We also offer rubber tubing for other automated banding machines. Our rubber tubing is designed to flow through automated banding equipment without frustrating jams and breakages. It’s available in a variety of colors and sizes – including custom imprint.

Our Banding Machines and Rubber Tubing are Made in the USA.

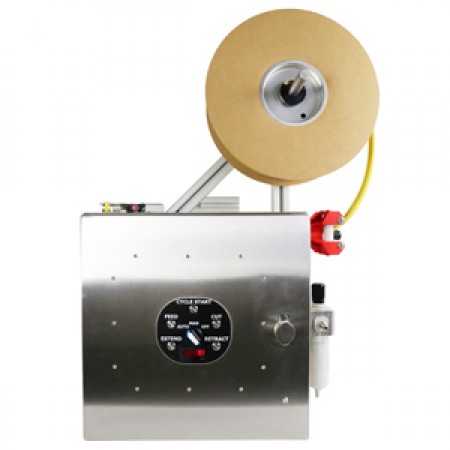

Automatic Banding Machine

The Automatic Banding Machine loads, stretches, and applies each band from a continuous roll of tubing. It provides a much more efficient method for applying rubber bands without damaging your product. These machines have been customized to band seafood and to secure industrial parts and pieces prior to shipping. They’ve proven to be useful across a wide range of industries and within multiple areas of operations.

The Automatic Banding Machine loads, stretches, and applies each band from a continuous roll of tubing. It provides a much more efficient method for applying rubber bands without damaging your product. These machines have been customized to band seafood and to secure industrial parts and pieces prior to shipping. They’ve proven to be useful across a wide range of industries and within multiple areas of operations.

Enhance the quality of your branded item by purchasing printed rubber tubing with your banding machine. Simply include your name, logo, or contact information to increase exposure or provide traceability information.

Automatic Banding Machines:

- Increase productivity

- Offer custom automated system options

- Eliminate repetitive motion injuries

- Provide latex free options for medical products

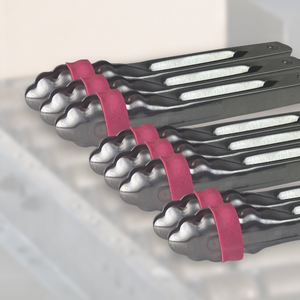

HPP & Oyster Banding |

Industrial Packaging |

Compact Dimensions |

|---|---|---|

| Whether your operations require manual banding for shipments of fresh oysters or as a part of your High-Pressure Processing system, the Oyster Banding Machine provides consistent application and ensures the best flavors and juices are sealed inside. | From banding multi-packs for promotional periods to securing products prior to shipment, our Banding Machines offer seamless integrated into any existing production line. Additionally, you will limit single-use plastic waste by choosing reusable rubber bands. | Our Banding Machines are easy to relocate due to their compact dimensions. This makes them ideally suited to short-term or long-term projects. Their durable stainless-steel construction allows them to perform well in demanding production environments and harsh marine conditions. |

Rubber Tubing

Alliance also provides rubber tubing to work with other rubber banding machines (such as the Strauss GUB Buncher, Cube Automation’s SmartBanding™ Machine, and Ramsay Highlander’s Harvesting Systems).

Our experienced staff is knowledgeable about the industries we serve and their application requirements. We work closely with each customer to ensure that our rubber profile or tubing meets the application requirements, part specifications and quality standards, and is delivered to you on time and installation-ready.

In-house compound mixing improves speed-to-market and quality control. Profiles are optimized by professionals who leverage our rubber extrusion manufacturing capabilities, materials expertise and full-scale rubber extrusion and compounding facility.

Industrial Products

- Direct Mail & Commercial Printers

- Facility & Moving Supply

- Dry Cleaners & Laundries

- Food Service

- Gaming, Banking, & Casinos

- Government & Military

- Gift & Novelty

- Health & Beauty

- Live Animal Supply

- Newspapers

- Medical & Pharmaceutical

- Office Supply / Stationery

- Packaging & Printed Products

- Tattoo & Body Piercing

- Produce, Floral, and Grocers

- Thrift Store & Resale Shops

- Seafood & Commercial Fishing

- Textile Manufacturing

- Direct Mail & Commercial Printers

- Facility & Moving Supply

- Dry Cleaners & Laundries

- Food Service

- Gaming, Banking, & Casinos

- Government & Military

- Gift & Novelty

- Health & Beauty

- Live Animal Supply

- Newspapers

- Medical & Pharmaceutical

- Office Supply / Stationery

- Packaging & Printed Products

- Tattoo & Body Piercing

- Produce, Floral, and Grocers

- Thrift Store & Resale Shops

- Seafood & Commercial Fishing

- Textile Manufacturing

Questions?

Contact us!

Alliance Rubber Company is a family-owned business with humble beginnings that has grown into a thriving American success story. Since 1923, Alliance Rubber has proudly produced rubber bands for use in the home and workplace. Continuing to manufacture its products in the USA, enables Alliance to provide high-quality products, fast service, and fresh stock that is built to last. Alliance Rubber, a women-owned company, manufactures bands that ‘Hold Your World Together.’