RUBBER BAND

UNIVERSITY

Welcome to the wonderful world of polymers! At Rubber Band University you will learn everything there is to know about our favorite invention – the glorious Rubber Band. From rubber band sizes to the history of rubber – you’ll find it all here. Click a topic below to get started on your journey.

All About Rubber

Learn the basics such as where rubber comes from, the history of rubber expansion across the globe, the different types of rubber compounds, and standard rubber band terminology.

Rubber Band Basics

Here you will learn about the different manufacturing processes of rubber bands, the different grades of rubber band products, rubber band sizes, and how to measure a rubber band.

Fun Facts

Can you name a feature film that includes Alliance Rubber Bands? Check out these fun facts and trivia and you will soon know the answer!

WHERE DOES RUBBER COME FROM?

NATURAL RUBBER CULTIVATION

Natural rubber is used for most rubber band production due to its superior elasticity. Most natural rubber plantations are located in Southeast Asian countries. Rubber trees can only thrive in hot, damp regions near the equator. Distinct from the sap, latex serves as a protective agent, sealing over wounds in the rubber tree’s bark. To “tap” the latex, rubber harvesters cut a wedge in the bark without cutting into the sap vessels. Latex oozes out and collects in a container attached to the tree. An average rubber tree yields 19 pounds of rubber latex annually.

Natural rubber latex is a bio-based, rapidly renewable resource. Rubber trees are not harvested and must be six years old before tapping for rubber can begin. they are then tapped for up to 28 years and help maintain the global carbon balance in the atmosphere throughout their lifetime.

HOW WAS RUBBER DISCOVERED?

MESOAMERICA

Mesoamerica refers to the region in central and southern Mexico and on into Guatemala in Central America where advanced native civilizations such as the Olmec people (followed by the Mayans and Aztec) thrived.

The Olmec people would collect the neat, milky-white sap they collected from the Hevea trees indigenous to their area, mix it with the juices from morning glory vines, and work it into balls to create an old age version of the kick ball.

This is the first archaeological evidence of the beginnings of rubber.

THE MAYANS

Time marches on and the Mayans continue to enjoy kickball as the Olmec people did. The Aztec people then take a huge leap forward by varying the ingredient proportions of latex to morning glory vine juices to create different strengths in the resulting product. They then used this surprisingly sturdy stuff to create leakproof containers and, by adding it to fibers, created waterproof clothing.

They used it to make sandals, jewelry and, of course, continued with the ever popular "gooey stuff" balls.

Remember, the word "rubber" doesn't exist yet.

EUROPEAN EXPLORERS

The Spanish conquistadors (under the leadership of Hernan Cortes) overthrew the Aztecs in 1521. The spoils they brought home included the gold they were after but also included the substance that later would become known as rubber.

In Europe (around 1770), Joseph Priestley observed that the material was extremely good at rubbing off pencil marks on paper and it became known as "rubber."

This was an era of expansion and trade and rubber slowly made its way east.

WHAT IS

SYNTHETIC RUBBER?

Synthetic rubber is a complex chemical compound that is created by refining oil, coal or other hydrocarbons into naphtha. The naphtha, a flammable liquid hydrocarbon mixture, is then combined with natural gas to produce monomers. Synthetic rubber (Polyisoprene) is petroleum-based and lends itself to brighter colors and better adhesion of ink for printed bands . Synthetic rubber is also classified as “non-latex” making it a solution for the 3-5% of the world population who are affected by latex allergy reactions.

Want to learn more about Non-Latex® Products for the Healthcare Industry?

WHAT OTHER TYPES OF RUBBER COMPOUNDS ARE COMMONLY USED?

THE HISTORY OF RUBBER BANDS

- 1843 - The first rubber band was developed when an Englishman named Thomas Hancock sliced up a rubber bottle.

- 1845 - Thomas Perry patented the rubber band and opened the first rubber band factory.

- 1923 - William H. Spencer founded Alliance Rubber Company in Alliance, OH.

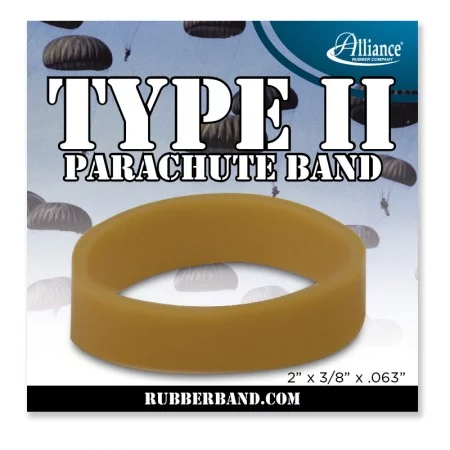

- 1957 - The open ring design was patented by Alliance Rubber Company.

- 1969 - Alliance Rubber Company installed the world's first Continuous Cure Band Production Line with extremely high production efficiencies.

COMMON RUBBER BAND TERMINOLOGY

MODULUS: Ratio of stress to strain. Also expressed as the tensile strength at a given percentage of elongation.

ELONGATION: The extension or “stretch” of a rubber band.

BREAK STRENGTH: Whether a band can withstand normal strain.

MEMORY: The ability of a rubber band to return to its original shape after being stretched.

LONGEVITY: This term is used to describe the length of time a rubber band can be used over a period of time without breaking.

COUNT PER POUND (CPP): The number of bands in a pound.

MANUFACTURING RUBBER BANDS

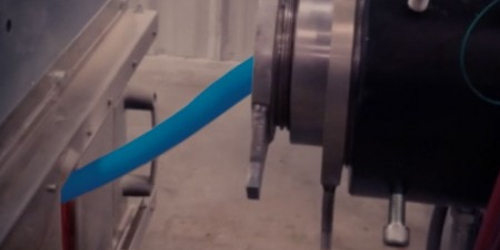

Bales of rubber and other ingredients (such as dyes, curing agents, etc.) are put into a large mixer, called a Banbury mixer, to create 400-pound batches.

This batch is then carried by a conveyor to the Rubber Mill where it is flattened into a sheet and cut into strips that are 1″ thick by 36″ wide.

The strips are fed into an extruding machine which forces the rubber out in long hollow tubes (similar to a garden hose).

The extruded tube travels through a salt bath and then into a cutting machine to cut different widths of bands.

Many overseas manufacturers use different processes such as dipping and steam curing.

GRADES OF RUBBER

Grades of rubber bands are typically tied to rubber content in the compound – from highest to lowest. For instance, there are four standard grades of rubber bands produced by Alliance Rubber Company. We have designed these specific compounds with varying stretch performance to create application specific bands (soft stretch vs. tight stretch).

OF RUBBER CONTENT

Pale Crepe Gold® delivers the very best experience for customers who require a band for repeat application and for packaging pliable goods where the ultimate soft hold is most important.

HIGHER PERCENTAGE

OF RUBBER CONTENT

Sterling® offers a soft hold and the best cost per rubber band. They are ergonomically correct and offer a perfect balance between elasticity and a firm hold. These provide the best value for all needs.

RUBBER CONTENT

Advantage® is designed with a mid-range rubber content to be a sturdy band with a firm stretch. These bands are perfect for everyday use and offer a good band count-per-pound.

OF RUBBER CONTENT

Global Rubber Bands are designed with the lowest amount of rubber content to be our most price competitive. They offer a thick wall with a tight stretch, without a guaranteed count-per-pound.

RUBBER CONTENT AND COUNT PER POUND

Rubber content is important but can also be a “red herring.” The quality of a rubber band as well as the count per pound can be improved not only with rubber content, but also with overall formulations and production methods. For instance, a higher quality band is achievable with less rubber.

A typical user may not see any discernible difference between our 53% rubber content and a 65% content from an inferior method and formula. Adding to the confusion, the US Trade Commission recently determined that overseas manufacturers use “inconsistent methods of rubber content calculation” and that there are “general industry misperceptions and/or false portrayals of rubber content” that are “inconsistent with rubber production.” For instance, it is impossible to achieve a rubber band using 100% rubber content, as other materials are needed to cure the band.

The most important thing to remember is that bands are offered for sale on the basis of weight. However, they are used one at a time.

A side-by-side comparison of functionality as well as an evaluation of the real cost of each band is usually required to determine the true value.

HOW ARE RUBBER BANDS SIZED?

There are several hundred commonly used rubber band sizes with three dimensions to consider when measuring.

A rubber band is usually measured in three basic dimensions: flat length, cut width, and wall thickness. Its flat length is defined as half its circumference. Its wall thickness is the distance from the inner surface to the outer surface, and its cut width is the distance from one cut edge to the other.

Rubber bands are numbered from smallest to largest, starting with the smallest cut width first. Therefore, rubber band sizes 8-19 are the smallest standard cut width: 1/16 inch. They’re then ordered by flat length from 7/8 inch to 3-1/2 inches.

Rubber band sizes 30-35 are the next category at 1/8 inch cut width. For bands with a flat length over 3-1/2 inches, the numbering starts over at 100. Again, these rubber band sizes are organized by cut width and then flat length – starting at cut width 1/16 inch.

The origin of these size numbers is not clear. For the most part, the most widely accepted size numbers can be found using our Standard Line Specifications Chart.

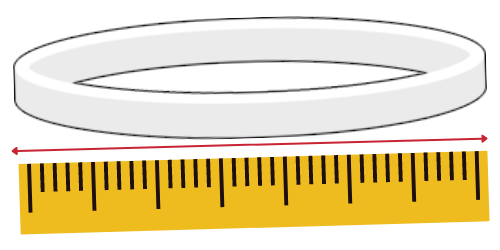

HOW TO MEASURE A RUBBER BAND

FLAT LENGTH

Measured by pinching two ends of the band together on a flat surface. the measurement from end to end equals the flat length.

CUT WIDTH

The measurement across the band perpendicular to the flat length. The wider the cut width the tighter the hold.

WALL THICKNESS

Measured by placing your thumb inside the band and pinching the portion between your thumb and forefinger, usually measured with a Starrett Gauge.

Currently it grows on plantations in Indonesia, Malaysia, Thailand, and the west coast of Africa.

The name "rubber" refers to the ability of the substance to rub off markings.

It was declared useless because it was gummy in the summer, stiff in the winter, and it rapidly deteriorated.

The Masticator allows the rubber to be softened, mixed, and shaped. It was invented by Thomas Hancock in London in 1820.

Primitively, rubber bands were first debuted in 1823.

Vulcanization is the heating of rubber to cause a chemical change and providing it with elasticity.

Stephen Perry, a British inventor and businessman.

The bands would encircle the globe fifty times or cover the distance between the earth and the moon 5-1/2 times!

Rubber bands last longer when refrigerated.

FAMOUS RUBBER BANDS